ZONESUN

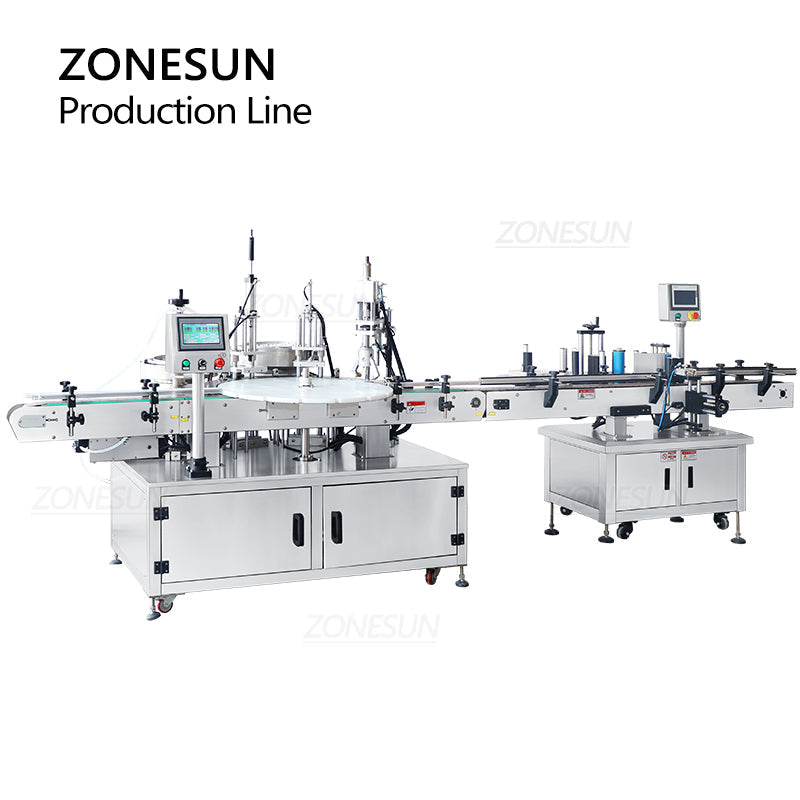

ZONESUN ZS-FAL180A10 Single Nozzle Peristaltic Pump Liquid Filling Cap Feeding Screwing Round Bottle Labeling Production Line

ZONESUN ZS-FAL180A10 Single Nozzle Peristaltic Pump Liquid Filling Cap Feeding Screwing Round Bottle Labeling Production Line

Verfügbarkeit für Abholungen konnte nicht geladen werden

DESCRIPTION

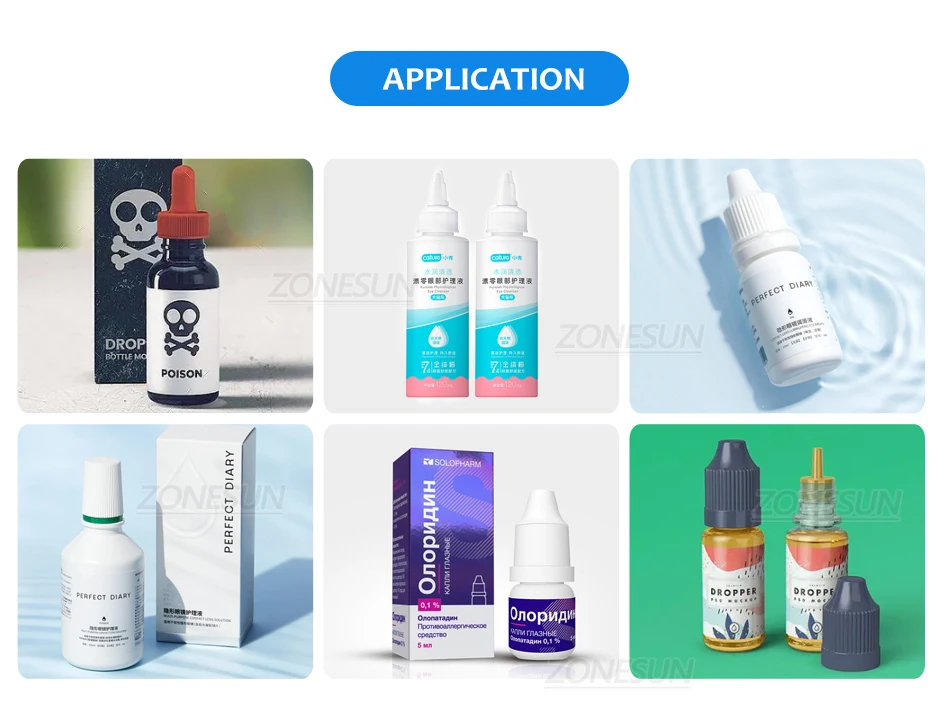

This automatic production line is designed with multiple functions. It can arrange bottles, fill liquid, feed bottle plugs and caps, cap bottles, and label stickers automatically. This is suitable for essential oil, eye drops, etc. We can customize the machine and make it can work for different sizes of containers at the same time.

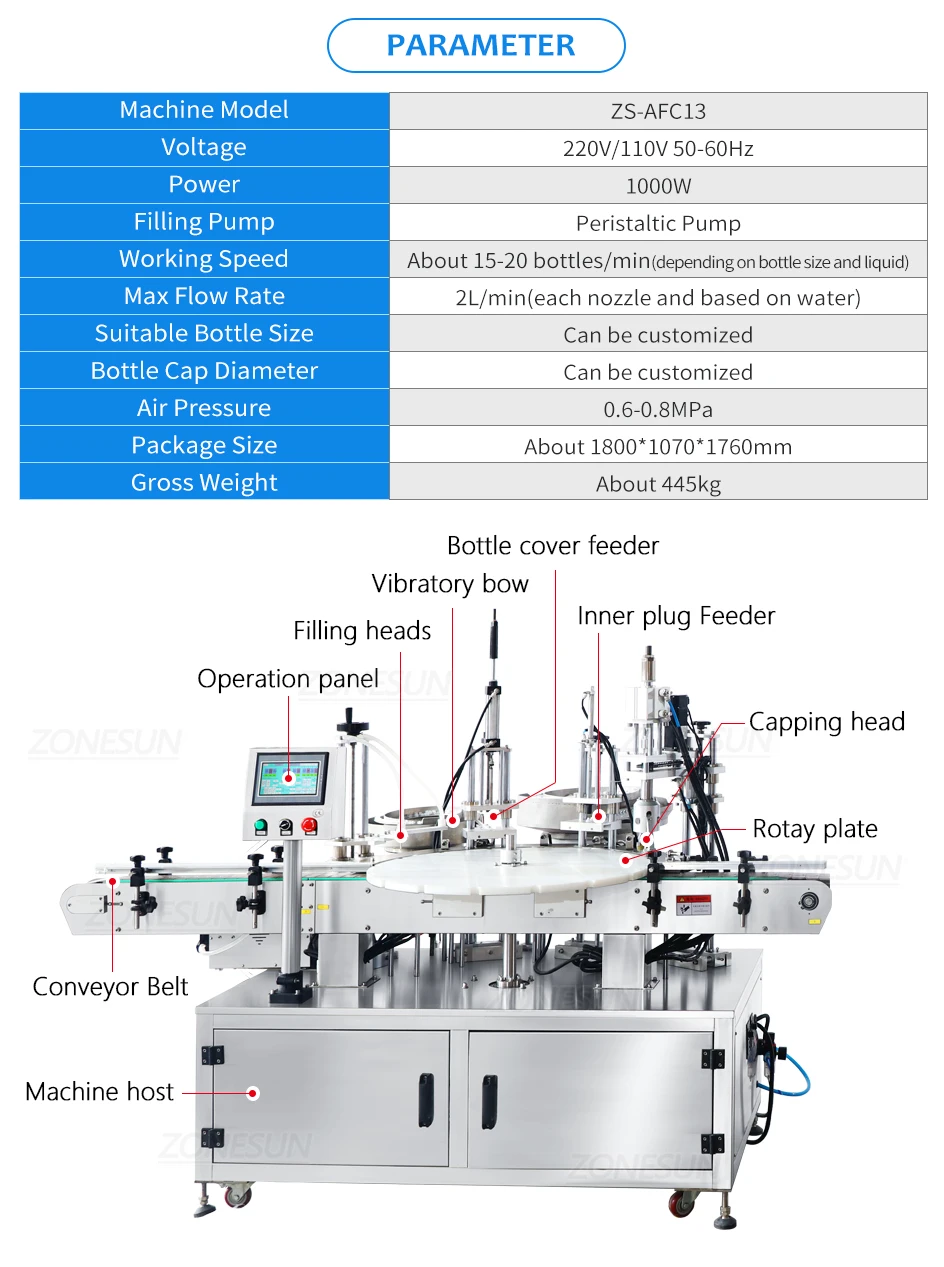

PARAMETER

|

FILLING & CAPPING MACHINE |

|

|

Machine Model |

ZS-AFC13 |

|

Voltage |

220V/110V 50-60Hz |

|

Power |

1000W |

|

Filling Pump |

Peristaltic Pump |

|

Working Speed |

About 15-20 bottles/min (Depending on bottle size and liquid) |

|

Max Flow Rate |

2L/min (each nozzle and based on water) |

|

Suitable Bottle Size |

Can be customized |

|

Bottle Cap Diameter |

Can be customized |

|

Air Pressure |

0.6-0.8MPa |

|

Package Size |

About 1800*1070*1760mm |

|

LABELING MACHINE |

|

|

Model |

ZS-TB260R |

|

Power Supply |

AC220V 50Hz/60Hz 1000W |

|

Labeling Capacity |

25-50 bottles/min(depending on bottle size) |

|

Labeling Accuracy |

±1.0mm |

|

Suitable Bottle Diameter |

Φ12-100mm |

|

Label Size |

(L)20-300mm (H)15-150mm |

|

Roll Inside Diameter |

Φ76mm |

|

Roll Outside Diameter |

Φ350mm |

|

Conveyor Size |

112*2000mm(W) |

|

Machine Size |

About 2000*820*1380mm |

|

Package Size |

About 2100*890*1520mm |

|

Net Weight/Gross Weight |

About 180kg/250kg |

PRODUCT DETAILS

CONTROL PANEL

With PLC controls, it’s easy to set working parameters.

FILLING

Peristaltic pump, the heads can be controlled separately.

FEEDING 1

Inner stopper, sucker design.

FEEDING 2

Overcaps, tapping

CAPPING

For screw caps only, with a sensor.

It keeps screwing until the cap is tightened.

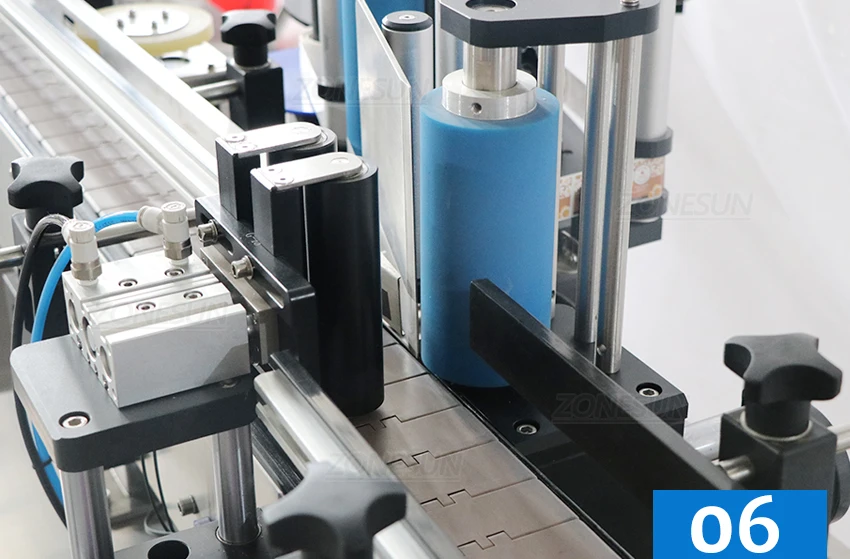

LABELING

Cylindrical bottles, customizable for double-sided labeling.